Mobile professional pressure washers with double boiler up to 100°C

acqua e fuoco

nvy 2b

Easy-to-handle, mobile and compact high-pressure washers, equipped with a system of two high-performance boiler units that allow high temperatures to be reached at high flow rates.

The 41 L/min models reach a temperature of 70°C at full flow and the 30 L/min models, a temperature of 90°C. On request, we produce models with a lower flow rate that reach a temperature of 100°C.

All the quality and reliability features of the Acqua e Fuoco range with increased heating power.

watch the video of the MODEL

ACQUA E FUOCO

NVY 2B 21.200

The NVY 2B 21.200 model has been created in a special version to meet the needs of a specific target of users who require very high temperatures (100 °C) for sanitising. Ideal in the agri-food industry, especially in the wine sector.

PROFESSIONAL HIGH-PRESSURE CLEANERS BUILT USING

ONLY THE VERY

BEST COMPONENTS

Motori servizio continuo S1

I motori elettrici offrono elevate prestazioni stabilizzando la temperatura di esercizio in valori costanti per un utilizzo illimitato grazie al servizio continuo in S1.

La potenza del motore scelta per l’accoppiamento alle pompe è sempre sovradimensionata in modo che la potenza richiesta dalle pompe non raggiunga mai i valori massimi disponibili.

Pompe professionali 1450 rpm

Le pompe in linea a 3 pistoni in ceramica sono ampiamente sovradimensionate, permettendo l’utilizzo solo parziale della pressione massima per cui sono state progettate.

Questa caratteristica, unitamente a quella dei motori elettrici in servizio continuo S1, permette alle idropulitrici Indra di lavorare senza pause di raffreddamento.

L’accoppiamento pompa-motore non è diretto, bensì è realizzato mediante giunto elastico per permettere che nel tempo, in caso di rottura del sistema di accoppiamento, l’intervento sia di lieve entità e rapido e non con la prospettiva di grosse operazioni di sostituzione di componenti.

Sistemi di sicurezza avanzati

Le idropulitrici Indra sono dotate di una solida scheda elettronica, specificamente progettata, che gestisce le funzioni della macchina e tutte le segnalazioni.

Tutte le funzioni e segnalazioni vengono gestiti in completa sicurezza, garantendo la risoluzione immediata di eventuali guasti. La gamma è infatti dotata di sicurezze avanzate e la scheda elettronica segnala al riparatore, con appositi led posti sul circuito stampato, il corretto funzionamento o eventuali avarie dei componenti elettrici. Vi è inoltre una segnalazione completa delle funzioni direttamente sul pannello comandi per consultazione e controllo da parte dell’utilizzatore.

areas of application

• Wine companies • Washing of bottling lines • Washing barrels, tanks also in combination with rotating heads • Vehicle washing • Car repair • Food industries • Charcuterie and cheese factories • Meat processing and distribution • Poultry farms for cleaning and sanitation of breeding areas • Livestock farms for cleaning and sanitising delivery, feeding and breeding rooms • Milking plants • Egg producers • Washing of operating rooms and mobile packaging lines • Food storage companies • Mechanical industries • Chemical industries • Fish processing and distribution industries • Production of ready-made and precooked food • Washing in covered food and fruit markets • Construction sites • Shipyards • Airports • Mechanical industries for washing at the end of processing cycles.

DESIGNED TO LAST

AND FOR CONTINUOUS OPERATION

Robust, compact and high-performance professional mobile high-pressure washers equipped with a dual high efficiency boiler system.

The Acqua e Fuoco range stands out for the high reliability of its components and for its versatility of application; they are sturdy professional high pressure washers, designed to last.

The tanks are rotomoulded and integrated into the structure to ensure high capacity and durability. The high and constant thickness makes them extremely robust and impact resistant.

The only mobile high-pressure cleaner equipped with DOUBLE WATER HEATER AND 21l rotoformed water tank

The NVY 2B models from the Acqua e Fuoco range have been designed keeping all the performance, quality and safety features of the NVY models with the addition of a double boiler system to ensure high temperatures even with high flow rates.

Large-capacity water tank which, thanks to its vertical shape, allows perfect feeding of the pump, which always receives water under pressure and without air bubbles.

The typical structure that distinguishes our high-pressure cleaners makes them easy to handle and practical to use, and allows them to take up little floor space despite the fact that the structure can house high-power pump-motor units (15 HP).

Highly professional electronic system: on the electronic board, several micro-led lights inform maintenance staff of the origin of possible malfunctions.

All functions and alerts are safely managed, ensuring immediate resolution of any faults.

The range is equipped with advanced safety features and the electronic board indicates the correct operation or possible failures of electrical components by means of micro-leds on the printed circuit board.

There is also a complete display of functions on the control panel for user reference and control.

High-performance electric motors that stabilise the operating temperature at constant and perfectly suitable values and

extensively oversized 3 ceramic piston inline pumps that only partially use the maximum working pressure for which they have been designed

allow each model to be used continuously without the need for cooling pauses.

The pump-motor connection is by means of an elastic coupling located in the gap between the two motor flanges.

The motor power chosen for coupling to the pumps is always oversized so that the power required by the pumps never reaches the maximum available values.

THE NVY 2B RANGE, THANKS TO its DOUBLE SYSTEM OF HIGH EFFICIENCY BOILERS, IS IDEAL FOR

WINE INDUSTRIES

High-powered pressure washers with high heating power, extremely professional and high-performance, but at the same time easy to handle and compact thanks to their specific structure and two frontal directional wheels.

DISCOVER THE MODELS

IN DETAIL

technical data

| MODEL | PRESSURE | DELIVERY | PUMP RPM | MOTOR POWER | POWER SUPPLY | MAXIMUM TEMPERATURE | DIMENSIONS |

|---|---|---|---|---|---|---|---|

| NVY 21.200 2B | 200 BAR | 21 L/min | 1450 rpm | 10 HP | 3ph - 9 kW | 98 °C * | 112x65x122 cm |

| NVY 30.200 2B | 200 BAR | 30 L/min | 1450 rpm | 15 HP | 3ph - 13,5 kW | 90 °C * | 112x65x122 cm |

| NVY 41.140 2B | 140 BAR | 41 L/min | 1450 rpm | 15 HP | 3ph - 13,5 kW | 70 °C * | 112x65x122 cm |

* The temperature values indicated are calculated at maximum flow rate.

DISCOVER ALSO THE RANGES

DISTINCTIVE FEATURES

OF THE RANGE

Durable, impact-resistant and compact: • Structure consisting of a tubular frame and a thick platform, mounted on 2 fixed and 2 pivoting wheels for great manoeuvrability • Thick stainless steel front and top covers, removable for efficient and immediate routine maintenance • 3 ceramic piston pump • 1450 rpm electric motor, continuous duty S1 • Motor-pump elastic coupling • Pressure control valve • Safety valve • Very robust, large-capacity integrated rotomoulded tanks • Anti-limescale product dosing pump, controlled by electronic board • Water filter • Fuel filter system with 3 additional filters.

the tanks

The 21 L water tank has been designed to have an enormous capacity and difference in height between the water inlet and the suction, which enables the pump to be supplied with constant pressure, to avoid the intake of air bubbles and to compensate for possible insufficient inlet pressure.

The 24L fuel tank is very large and has an internal level sensor that seals by contact with a gasket and not by expansion of a rubber ring. It also has a drain plug at the bottom.

The 2L anti-limescale tank is located inside the machine and is equipped with a level sensor and dosing micro-pump. A warning light on the control panel will indicate that the pump has stopped due to lack of anti-limescale liquid. The micro-pump will start up again after refilling.

safety systems

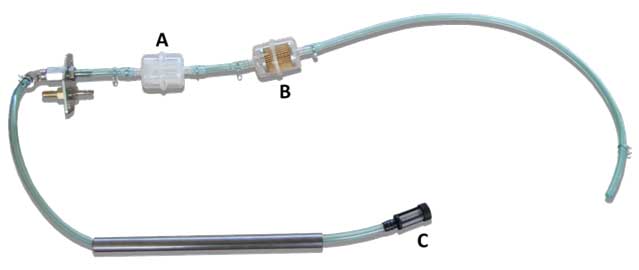

NVY 2B is protected by a multiple security system: With regard to combustion, safety in the Acqua e Fuoco range is guaranteed by a microswitch (5), a pressure switch (4) and a flow switch (1). The burner start and stop functions are regulated by sensing both water flow and pressure.

If one of the devices fails, signalling lack of flow or pressure, combustion is in any case immediately stopped or burner ignition is not permitted.

This multiple system gives an extra guarantee that combustion will stop even if the water no longer circulates in the coil, avoiding the risk of overheating.

- Flow switch (1)

- Safety valve (2)

- Pressure regulator (3)

- Pressure switch (4)

- Microswitch (5)

CONTROL PANEL

Simple and intuitive 24V control panel, complete with: • Pump start switch • Boiler start switch • Machine stop switch • Tension indicator • Pump in operation indicator • Boiler in operation indicator • No fuel warning light • Lack of limescale indicator • Thermostat • Pressure gauge • Pressure and flow regulation valve.

Timed intelligent total stop: motor stops after 15 seconds with gun closed; total stop after 10 seconds of operation without water; total stop due to accumulation of 10 microleaks; safety system that disables all functions when the motor is not started within 60 minutes.

Sturdy and impact-resistant

The supporting structure consists of a tubular frame and a thick platform.

The frame is cataphoresis-treated and then painted with epoxy powders. This treatment provides greater resistance over time.

Complementing the bodywork are two covers, one at the front and one at the top, made of thick stainless steel.

- Control of all functions and advanced safety systems with LED signalling on the operating panel:

- Pump in operation indicator.

- Safety stop signalling after a power failure.

- Micro leak detection indicator.

- Boiler in operation indicator.

- Stop for intervention of combustion control system indicator.

- Lack of limescale indicator.

- Fuel reserve warning light.

- Complete and intuitive control panel.

attention to every detail

Its characteristic vertical structure not only allows the considerable technical advantages described above, such as the constant pressure supply of the pump, but is also extremely ergonomic. The handles at the back, unlike conventional high-pressure cleaners, are positioned at the correct height and make it easy to move the cleaner.

An additional wheel is placed on the back of the structure making it easy and safe to move the cleaner, allowing the front to be raised slightly to overcome possible unevenness in the ground.

The diesel filler cap at the rear is in a convenient position.

The typical structure of the Acqua e Fuoco range makes it possible to house two high-efficiency boilers and high-power pump-motor units (up to 15 HP) in a reduced floor space, equal to that of small semi-professional high-pressure washers.

DIESEL FILTRATION

Diesel oil filtration system consisting, for each boiler, of:

A. Pre-filter, for the retention of coarse particles (120 µm)

B. Cartridge filter to retain the finer impurities (31 µm)

C. Self-cleaning filter immersed in diesel to prevent suction of processing residues. A counterweight keeps it constantly on the bottom.

The adoption of this triple filtration system does not allow the operation of the diesel pump to be altered, keeping the small emergency filter with which it is equipped clean at all times.

EASY AND QUICK ACCESS TO INTERNAL COMPONENTS

When designing the Acqua e Fuoco range, great consideration was given to immediate access to each of its components.

Simply remove the front and top covers for easy access to the main components. For more in-depth maintenance, the entire tank block can also be removed for full access to the components.

extremely high-performing boiler units

- Larger dimensions compared to common cleaners.

- Long heating coils.

- Low noise emissions.

- Low flow diesel nozzles and high temperatures.

- Low smoke emission: between 0 and 1 on the Bacharach scale.

- High efficiency and fuel savings.

- Fans made of painted steel, resistant to vibration.

high performance and low emissions

NVY 2B is designed and refined for maximum efficiency. The two combustion chambers work in synergy to ensure maximum performance: high temperatures even at high flow rates and minimal smoke emissions.

are you interested in professional hot water pressure washers?

We will be happy to help you choose the best pressure washer.

STANDARD ACCESSORIES FOR

PROFESSIONAL USE

The accessories are for professional use, in compliance with safety regulations. The included 15 m high-pressure hose allows to wash large equipment at a safe distance from the cleaner.

- 15m blue non-staining high pressure hose.

- Spray gun with extension.

- Removable lance terminal for quick use of extra accessories.

- High pressure nozzle.